Custom Aluminum Profiles: The Aluminum Extrusion Process and Its Applications Across Industries

Introduction

Henan Ychgd Trading Co., Ltd. specializes in custom aluminum profiles, a crucial lightweight material in industries like construction, transportation, electronics, and machinery manufacturing. With the increasing demand for these profiles, the aluminum extrusion process is key to shaping materials into diverse forms that meet specific application needs. This article delves into the principles of aluminum profiles, the extrusion process, and their application prospects.

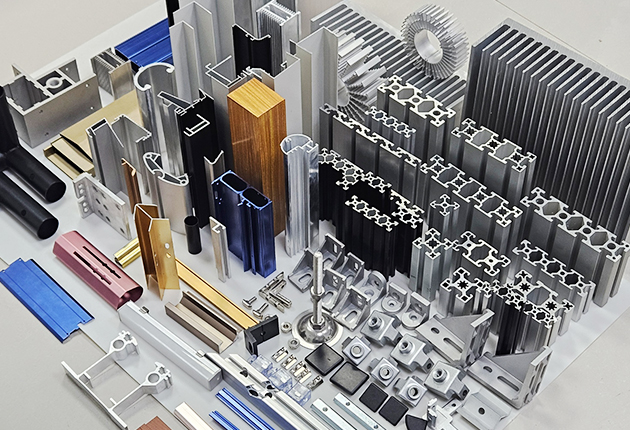

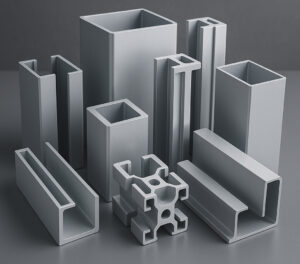

Understanding Aluminum Profiles and Extrusion Technology

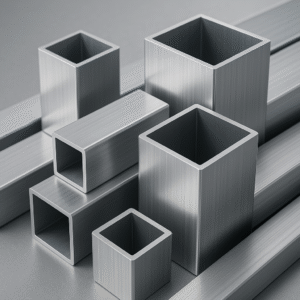

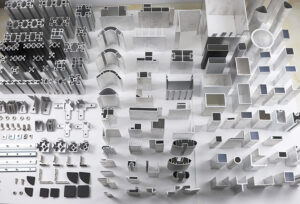

Aluminum profiles are shaped through the aluminum extrusion process, which involves heating and pressuring aluminum alloy materials through a die. This technology enables precise, customized shapes with high mechanical properties, making profiles suitable for industrial and commercial projects like frame structures, windows, and transportation vehicles.

Advantages of Custom Aluminum Profiles

- Precision in Sizes and Shapes

Henan Ychgd Trading Co., Ltd. excels in creating custom aluminum profiles with micrometer precision, ideal for complex structures and customer-specific needs, from equipment casings to building materials. - Lightweight yet Strong

Our custom profiles combine the inherent corrosion resistance and strength of aluminum alloys, reducing weight while maintaining structure, thus cutting transportation costs. - Energy Efficiency and Eco-Friendliness

Aluminum profiles are recyclable, contributing to environmental sustainability. With advanced surface treatments like anodizing and powder coating, they offer versatility and enhanced durability for various applications.

Industry Applications

- Construction

In modern architecture, aluminum profiles are vital for window frames, curtain walls, and balcony railings. Their lightweight nature aids in aesthetics and wind resistance for building facades. - Transportation

Aluminum profiles in automotive, train, and aircraft manufacturing optimize body structures and fittings, thereby reducing fuel consumption and emissions—a step towards greener transportation. - Electronics

Known for excellent heat dissipation, our custom aluminum profiles are ideal for electronic device casings and LED systems, ensuring long-term stable operation. - Machinery Manufacturing

In robotics and automation, custom profiles can be tailored to equipment design, enhancing structural forms and boosting production efficiency.

Future Trends in Aluminum Profiles

Technological advancements are enhancing aluminum extrusion precision and efficiency. Henan Ychgd Trading Co., Ltd. is at the forefront of this evolution, meeting the demand in green construction and smart manufacturing with custom solutions.

- Intelligent Customization

With AI and big data, profile customization becomes more responsive to market needs, utilizing automated production for flexibility and speed. - Green Aluminum Profile Initiatives

Environmental standards drive manufacturers like Henan Ychgd Trading Co., Ltd. to focus on energy savings and sustainability in production, prioritizing eco-friendly processes.

Conclusion

Aluminum profiles are a high-performance, versatile material across industries. With innovation in extrusion technology, custom profiles are increasingly precise and applicable. Henan Ychgd Trading Co., Ltd. offers industry-leading solutions for those seeking custom profiles or insights into extrusion technology. Contact us for professional support and solutions tailored to your needs.