How to Produce Aluminum Profiles?

Introduction

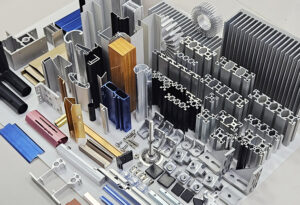

Aluminum profiles are widely used in construction, transportation, and manufacturing due to their lightweight, corrosion resistance, and high strength. Henan Ychgd Trading Co., Ltd. leverages its advantages to provide customers with high-quality aluminum profile solutions. This article explores the production process of aluminum profiles, offering insights for industry newcomers.

Production Process

- Raw Material Preparation

- Material Selection and Analysis Equipment

Selecting high-quality aluminum alloy is crucial in the initial stage of production. Henan Ychgd uses advanced spectrometers to perform chemical analysis on aluminum ingots, ensuring their purity. Precise analysis guarantees that each batch of raw materials meets international standards, securing product quality from the source.

- Material Selection and Analysis Equipment

- Casting Process

- Furnace and Casting Technology

Aluminum ingots are fed into an electric furnace for melting at temperatures exceeding 600°C. Henan Ychgd employs hot top casting techniques, allowing molten aluminum to flow into casting molds to form stable castings. This technology reduces bubble formation, enhancing material quality. Our furnaces are equipped with automatic temperature control systems to ensure process stability.

- Furnace and Casting Technology

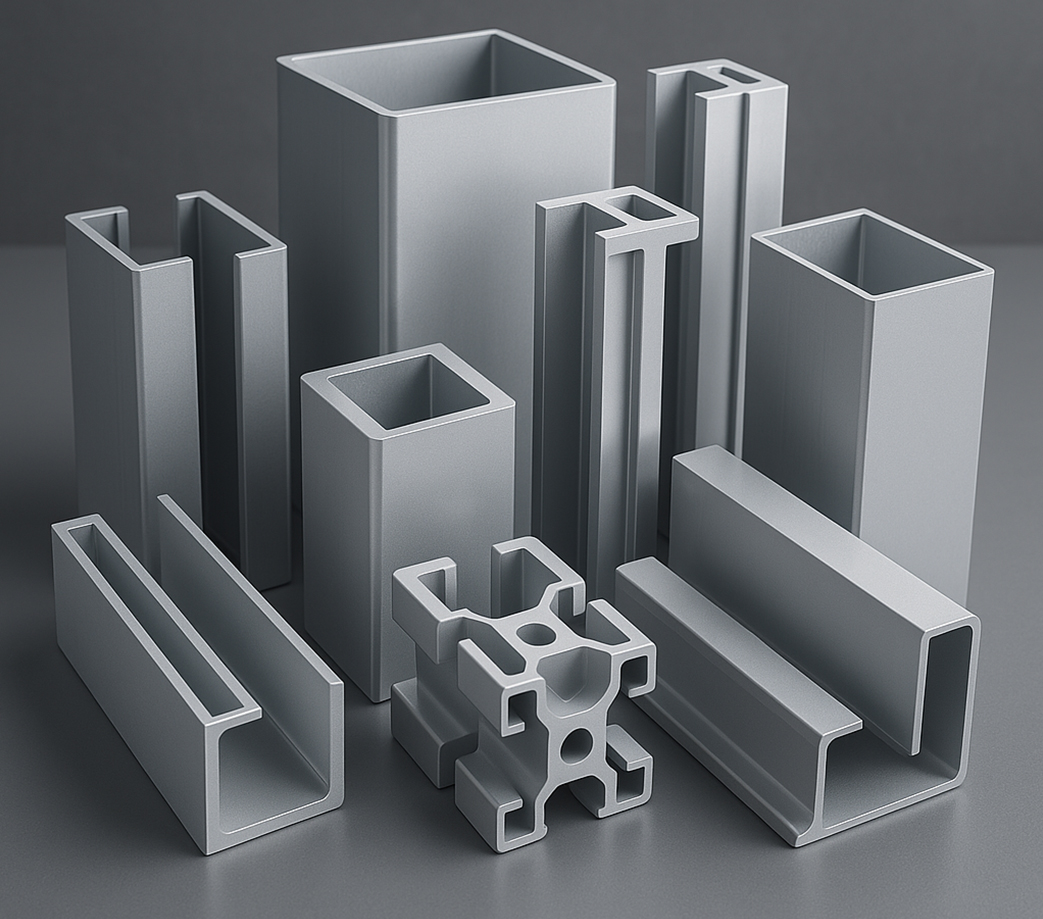

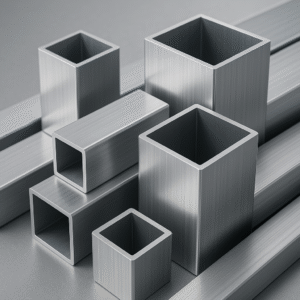

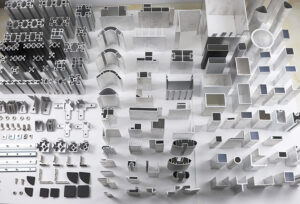

- Extrusion Forming

- Extrusion Machines and Mold Design

Molten aluminum is injected into molds through extrusion machines to form specific cross-sectional shapes. We use high-tonnage extrusion machines to apply immense pressure, enabling precise shape formation through molds. Henan Ychgd’s CAD design team handles mold design, utilizing 3D printing to create prototypes, ensuring mold precision and durability.

- Extrusion Machines and Mold Design

- Heat Treatment

- Heat Treatment Equipment and Technique Control

After forming, aluminum profiles require heating and cooling in specialized heat treatment furnaces. By precisely controlling temperature and time, we optimize material properties. Our heat treatment furnaces are equipped with data acquisition systems for process monitoring and adjustment, ensuring each batch achieves optimal hardness and durability.

- Heat Treatment Equipment and Technique Control

- Surface Treatment

- Oxidation and Coating Equipment

Surface treatment enhances the visual appeal and durability of aluminum profiles. Henan Ychgd offers various methods, including anodizing, electrophoretic coating, and powder spraying. Through automated coating equipment, we achieve efficient mass production, ensuring uniformity and quality. Customers can choose different colors and finishes to meet specific design requirements.

- Oxidation and Coating Equipment

- Inspection and Packaging

- Inspection Equipment and Packaging Solutions

Quality checks utilize CNC measuring machines and optical inspection equipment for comprehensive examination of dimensional accuracy and surface quality. Only after thorough inspection are profiles packaged. We employ shock-resistant packaging materials and customized logistics solutions to ensure product integrity during transportation.

- Inspection Equipment and Packaging Solutions

Sustainable Development

- Eco-friendly Technology and Material Selection

Henan Ychgd is committed to environmentally friendly production by using recycled aluminum and optimizing energy consumption across all processes. Through collaboration with suppliers, we promote the use of sustainable materials, striving for a greener aluminum profile production.

Conclusion

Producing aluminum profiles is a complex endeavor that encompasses each step from raw material preparation to final inspection. Henan Ychgd Trading Co., Ltd. uses advanced equipment and professional expertise to deliver superior aluminum profile solutions to customers worldwide. Our team is ready to offer support and services at any time. Feel free to contact us for more information or customized solutions.