What Is the Difference Between T6 and T52 Aluminum?

Understanding specific temper designations like T6 and T52 is crucial for optimizing material performance in aluminum alloy projects.

These designations refer to different tempering processes impacting strength, hardness, and formability. T6 is known for its strength, while T52 excels in formability and ease of fabrication. Choosing the right temper can significantly enhance project results.

Differences in Tempering Processes

T6 Aluminum

T6 aluminum undergoes solution heat treatment followed by artificial aging. This enhances strength and hardness, making it ideal for structural components in aerospace, automotive, and construction industries. Its resilience makes it perfect for high-stress applications.

T52 Aluminum

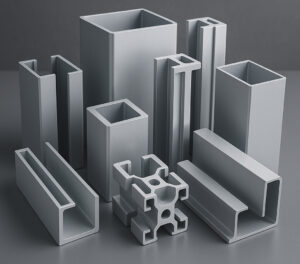

T52 aluminum undergoes a milder heat treatment, providing moderate strength and improved formability. This makes it excellent for complex shaping, such as in architectural projects and decorative elements.

Importance of Choosing the Right Aluminum Temper

The right temper impacts material performance, cost, and project suitability. T6 offers high strength but may not suit applications requiring intricate shapes. T52 provides design flexibility without sacrificing moderate strength.

Why Choose Henan Ychgd Trading Co., Ltd.?

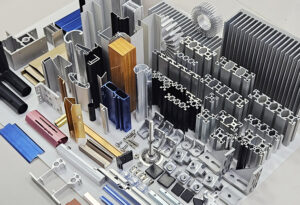

We offer expert guidance and high-quality aluminum products for various applications and temper requirements.

Technical Support and Expertise

Henan Ychgd provides comprehensive support to select the right temper. Our advanced technology and experienced team ensure quality and swift delivery.

Product Advantages

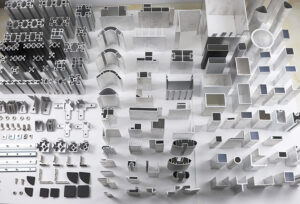

Our T6 and T52 aluminum products meet rigorous quality standards, offering superior performance. We also provide custom solutions for diverse applications.

In-depth Analysis

Understanding the difference between T6 and T52 aluminum is essential for selecting the right material. T6’s strength is indispensable for environments requiring resistance to wear, such as load-bearing structures.

T52 aluminum’s adaptability is ideal for projects with complex curves and shapes. Its enhanced formability supports innovative designs without compromising integrity, making it valuable in aesthetic and functional applications.

Assessing project specifications, environmental factors, and desired material properties helps in choosing the most suitable temper.

Conclusion

Choosing the right aluminum temper is key to successful applications. Understanding T6 and T52 properties ensures optimal outcomes. T6 suits strength-demanding tasks, while T52 offers design flexibility. Henan Ychgd Trading Co., Ltd. offers expert support and top-tier products for your project’s success.

Contact Us:

- Email: cncindy2003@gmail.com

- Phone/WhatsApp: +86 15713826082

- Website: ychgd.com

By understanding T6 and T52 aluminum applications and advantages, you can select the ideal material for project success. Henan Ychgd is ready to provide specialized guidance and support.